Features

The special structure design of the valve cage type and its own patented multi-stage buck labyrinth disc ensures the flushing and wear of the small opening moment and the air exhaust when the opening is fast.

The core has cage guidance, good stability and low noise. The valve flap has a double throttle piece, which can effectively protect the sealing surface and greatly extend the service life.

The valve trim is made of high-quality materials, hardened on the surface and has a long service life.

There is a balance hole on the valve flap to reduce the unbalanced force. The drive unit is light and easy to operate.

Imported GARLOK packing, good sealing performance, low friction coefficient, no damage to the valve stem.

Sealed surface overlaid with hard alloy, which is resistant to abrasion and corrosion and is resistant to erosion.

The modular design of the trim allows quick disassembly and replacement of trim on site, eliminating the need for cutting and welding valves, facilitating maintenance and reducing maintenance costs.

Performance Parameters

Nominal diameter: 1〞~10〞 (DN25~DN250)

Nominal pressure: Class 300 ~ Class 2500

Applicable temperature: ≤ 610 °C

Connection type: Welding, flange

Flow characteristics: Quick opening

Body material: A105, F22, F91, F92, etc.

Operation type: Electric, pneumatic operated with manual

Application Condition

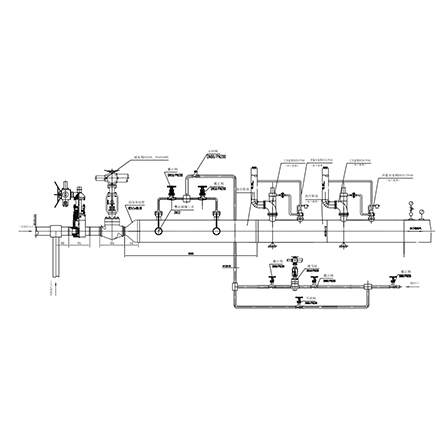

Air exhaust of main steam pipes and exhaust pipes in thermal power plants (including the self-supplied power plants).