Features

Overall die forging, forging ratio ≥4, compact structure and excellent mechanical properties. One-piece design, less leakage points, good sealing performance, safe and reliable, and effectively ensure long-term operation of the valve.

Straight-through channel, low flow resistance coefficient, no pressure drop, no heat loss.

Self-owned company material design standards, large wall thickness, effectively extending the service life.

Floating ball design, the ball has a large space for movement, and the ball seats are easy to align each other. The higher of the pressure, the more reliable the sealing.

90 degree rotation completes the valve switch, the switch is fast.

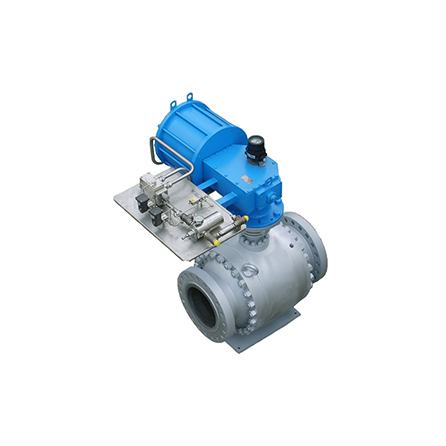

In power systems, there are many demanding applications requiring large diameter, high temperature, high pressure traps, isolation valves, and exhaust valves. Many alternative products, such as globe valves, cannot be completely shut down in such large diameter, high pressure, high temperature devices, and the service life is too short. In response to the above conditions, KOVOK developed a power plant-specific ball valve with a compact structure, moderate price and long service life to solve the above conditions.

Performance Parameters

Nominal diameter: 3〞~20〞 (DN80~DN500)

Nominal pressure: Class 150 ~ Class 600

Applicable temperature: - 29 ° C ~ 610 ° C

Connection type: Flange

Body material: A105, F22, F91, F92

Ball material: Inconel 718+ chromium carbide

Operation type: Handle, worm gear, electric, pneumatic

Application Condition

Main steam isolation, economizer isolation, bottom ash isolation, etc. of thermal power plants (including the self-supplied power plants).